Belt Tolerances and Specifications

.080” PITCH

Neoprene and TruMotion

BREAKING STRENGTH: 425 LBS PER inch OF BELT WIDTH

TEMPERATURE RANGE: -30°F TO 185°F

WIDTH TOLERANCE: see chart on page E60

.0816” PITCH (40 DP)

URETHANE POLYESTER CORD

BREAKING STRENGTH: 520 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: 0°F TO 180°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: ±.020” FOR BELTS 1/16”- 4” WIDE

.080” PITCH

URETHANE POLYESTER CORD

BREAKING STRENGTH: 520 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: 0°F TO 180°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: ±.020” FOR BELTS 1/16”- 4” WIDE

.0816” PITCH (40 DP)

URETHANE KEVLAR CORD

BREAKING STRENGTH: 1050 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: 0°F TO 180°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: ±.020” FOR BELTS 1/16”- 4” WIDE

.080” PITCH

URETHANE KEVLAR CORD

BREAKING STRENGTH: 1050 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: 0°F TO 180°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: ±.020” FOR BELTS 1/16”- 4” WIDE

1/5” & 3/8″ PITCH

URETHANE POLYESTER CORD

BREAKING STRENGTH: 630 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: 0°F TO 180°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: ± .020” FOR BELTS 1/16”– 4” WIDE

1/5” PITCH

URETHANE KEVLAR CORD

BREAKING STRENGTH: 2500 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: 0°F TO 180°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: ± .020” FOR BELTS 1/16”– 4” WIDE

3/8” PITCH

URETHANE KEVLAR CORD

BREAKING STRENGTH: 3000 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: 0°F TO 180°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: ± .020” FOR BELTS 1/16”– 4” WIDE

1/5” PITCH

Neoprene and TruMotion

BREAKING STRENGTH: 895 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: -30°F TO 185°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: see chart on page E6

3/8” PITCH

Neoprene and TruMotion

BREAKING STRENGTH: 920 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: -30°F TO 185°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: see chart on page E6

3 MM HTD PITCH

Neoprene and TruMotion

BREAKING STRENGTH: 920 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: -30°F TO 185°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: see chart on page E6

2 MM GT2 PITCH

Neoprene and TruMotion

BREAKING STRENGTH: 495 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: -30°F TO 185°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: see chart on page E6

5 MM HTD PITCH

Neoprene and TruMotion

BREAKING STRENGTH: 1800 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: -30°F TO 185°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: see chart on page E6

3 MM GT2 PITCH

Neoprene and TruMotion

BREAKING STRENGTH: 880 LBS. PER INCH OF WIDTH

TEMPERATURE RANGE: -30°F TO 185°F

LENGTH TOLERANCE: CENTER DISTANCE TOLERANCE ± .020”

WIDTH TOLERANCE: see chart on page E6

2mm, 3mm, 5mm, .080”, 1/5”- 3/8” PITCH

NEOPRENE AND TRUMOTION BELTS

TEMPERATURE RANGE: -30° F TO 185° F

TWIN POWER BELTS 1/5”– 3/8” PITCH

BLACK NEOPRENE FIBREGLASS CORD

TEMPERATURE RANGE: -30° F TO 185° F

STANDARD TIMING BELT WIDTH TOLERANCES

(FOR NEOPRENE AND TRUMOTION BELTS 2mm, 3mm, 5mm, .080”, 1/5” AND 3/8” PITCH)*

| BELT WIDTH IN. | WIDTH TOLERANCE ON BELT LENGTHS 0" TO 33" | WIDTH TOLERANCE ON BELT LENGTHS OVER 33" TO 66" | WIDTH TOLERANCE ON BELT LENGTHS OVER 66" |

|---|---|---|---|

| 1/8 TO 7/16 | +1/64 -1/32 |

+1/64 -3/64 |

+1/64 -3/64 |

| OVER 7/16 TO 1-1/2 | +1/32 -1/32 |

+1/32 -3/64 |

+1/32 -1/16 |

| OVER 1-1/2 TO 2 | +1/32 -3/64 |

+3/64 -3/64 |

+3/64 -1/16 |

| OVER 2 TO 2-1/2 | +3/64 -3/64 |

+1/16 -3/64 |

+1/16 -1/16 |

| OVER 2-1/2 TO 3 | +3/64 -1/16 |

+1/16 -1/16 |

+1/16 -5/64 |

| OVER 3 TO 4 | +1/16 -1/16 |

+1/16 -5/64 |

+5/64 -3/32 |

| OVER 4 | +3/32 -3/32 |

+3/32 -3/32 |

+3/32 -1/8 |

STANDARD NEOPRENE AND TRUMOTION TIMING BELT CENTER-DISTANCE TOLERANCES

| BELT LENGTH IN. | *TOLERANCE CENTER-DISTANCE IN. |

|---|---|

| 5 TO 10 OVER 10 TO 15 OVER 15 TO 20 OVER 20 TO 30 OVER 30 TO 40 OVER 40 TO 50 OVER 50 TO 60 OVER 60 TO 70 OVER 70 |

±.008 ±.009 ±.010 ±.012 ±.013 ±.015 ±.016 ±.017 ON APPLICATION ADD .001" FOR EVERY 10" SPREAD |

TWIN POWER TOLERANCES

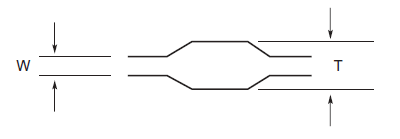

Since twin power belts are manufactured and cut to the required width by the same method as standard belts, the same manufacturing tolerances apply, except for the thickness and length tolerances which are shown in the following tables.

BELT THICKNESS TOLERANCES

| PITCH | T (IN.) | W (IN.) |

|---|---|---|

| 1/5-INCH (XL) 3/8-INCH (L) |

.120 ± .006 .180 ± .006 |

.020 ± .004 .030 ± .004 |

CENTER-DISTANCE TOLERANCES

| BELT LENGTH IN. | *TOLERANCE CENTER-DISTANCE IN. |

|---|---|

| 15 TO 20 OVER 20 TO 30 OVER 30 TO 40 OVER 40 TO 50 OVER 50 TO 60 OVER 60 TO 70 OVER 70 |

±.020 ±.024 ±.026 ±.030 ±.032 ±.034 (REFER TO FACTORY) |